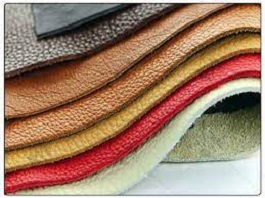

Types of leather tanning

There are different types of leather, each of which naturally has a special type of tanning. Of course, the leathers themselves also have different types of leather tanning and various tanning methods, which are discussed in this article.

Leather produced by tanning with chrome

The first and perhaps the most widely used type of leather tanning is chrome tanning. Tanning with chrome was used for the first time in 1858 and it used chrome sulfate and other chrome salts.

The leather produced in this method is softer and more flexible than the leather produced in the vegetable tanning process, and also, when this type of leather is exposed to water, it loses its shape and color less. This type of leather is sometimes called blue leather (blue color), which is the color of chrome itself.

When the tanning process with chrome is used, it is possible to create more special and strange colors. The process of tanning with chrome often takes a day, and the ease and speed of this method have made it a popular and widely used option.

In addition to all these, there are also environmental concerns about this chrome tanning method, which has caused other types of leather tanning to be used. However, international reports acknowledge that the leather produced by the chrome tanning process constitutes about 80% of the world’s leather production.

Leather produced by plant tanning

This method of tanning with plants is one of the types of leather tanning methods using tannins and other substances found in plant tissues such as bark, wood, fruit and tree roots. This leather is very soft and flexible and has a color similar to brown, but its exact color is related to the composition of the materials used in it, as well as the color of the animal’s skin.

This type of leather is the only type that is used for engraving and marking on leather. The leather produced by vegetable tanning is not resistant to water and loses its color over time. Also, if it is placed in water and then dried, it will wrinkle and harden.

This characteristic of leather produced from the bark of the oak tree is used in traditional shoemaking. This type of leather shrinks strongly in hot water and gradually hardens and eventually becomes crispy. An example of this application is tanned leather, where the leather is soaked in hot water or placed in baked wax or other similar materials to harden it.

Historically, this type of leather, after hardening, was mainly used to make armor, but it was also used to bind books.

Leather produced with aldehyde tanning

This type of leather is tanned using glutaraldehyde or oxazolidine (C3H7NO) compounds. Most tanners know this type of leather by the name of white leather, which is due to the colorless or white state of this leather. This leather is the main type of “chrome-free leather” that is used in making shoes for babies and in automobile manufacturing.

Leather produced with formaldehyde tanning

This method is another type of leather tanning using aldehydes. This method is becoming obsolete because of the dangers it poses to workers and because many people are allergic to formaldehyde. Brain tanned leathers are also one of the members of this family that have the ability to absorb water.

Leathers tanned with materials taken from animal brains

This type of leather is produced in a very difficult process in which emulsion oils are used. These oils are prepared from the brains of animals such as deer, cow and buffalo. These types of leather are famous for their extraordinary softness and washability.

suede leather

This type of leather is also included in the category of leathers produced with aldehyde tanning, and similar to leathers tanned with materials taken from animal brains, it produces porous leather with high water absorption. Suede leather is often produced using marine oils that easily oxidize and produce aldehydes that tan the leather and change its color.

Leather tanned with rose oil

This type of leather is another type of leather produced by vegetable oils in which pure rose oil replaces vegetable or emulsion oils. The leather obtained in this process will have a very strong rose scent even years later. This type of leather is also referred to as the most valuable leather on the planet. The reason for this value is the expensiveness of rose oil and also the difficult tanning process that requires a lot of work.

Artificial leather

This type of leather is tanned and produced using aromatic polymers such as phenolic resin or syntan (short for synthetic tannin). This type of leather is white and was invented when vegetable tannins were scarce during World War II. Melamine and other amino resins are also included in this category and are used as fillers in most new leathers.

Urea-formaldehyde resins were also previously used in this tanning method until it became clear what dangers formaldehyde can have for workers as well as consumers, and as a result, the use of urea-formaldehyde was abandoned.

Aluminum leathers

This type of leather is produced by combining aluminum salts with sticky materials and protein sources such as flour and egg yolk. From a technical point of view, it can be said that aluminum leathers are not tanned because tannic acid is not used in them, and also the material obtained from this process, if it is exposed to water for a long time, so that the aluminum salts are separated from it. , turns into untanned skin again.

Untanned skin

Similar to aluminum tanning, untanned leather is technically not classified as leather, but in many cases, it is used alongside other types of leather. Untanned leather is harder and more fragile than other types of leather.

Its application is mainly in cases where there is no need for much flexibility. For example, making drum covers and parchment paper are among the uses of this material. Also, in some cases, this material comes in the form of strings and it is used in making fittings or in sewing stitches in embroidered leather or for making teeth for dogs.

Result

Usually, the leather produced by vegetable tanning can be greased to increase its resistance to water. Considering that if the leather is repeatedly exposed to water, most of the oils in it are washed away, this leather-making process that takes place after the end of tanning as a supplement to the natural oils that remain in the leather itself , it works.