Polyurethane foam raw materials

Polyurethane is a group of chemicals that is synthesized from the reaction of two main substances, isocyanate and polyol. This combination is also seen with the abbreviation PU or PUR. This material is widely used in making insulation and implantable organs. Next, in addition to further introducing this product (polyurethane foam raw materials), we will examine its uses, properties and characteristics, price, purchase, sale, MSDS and possible complications of its use.

What is polyurethane?

Polyurethane or polyurethanes are a wide group of polymers that play a major role in our daily life.

These polymers are usually formed by the reaction of two main isocyanate and hydroxyl groups. Although they use alternative routes such as amines in certain cases.

These materials are broadly divided into three categories: cloud and sponge, hot foam and cold foam.

History of polyurethane

Polyurethane (PU) was first discovered by Otto Bayer in 1937. He is known as the father of polyurethane industry due to his discovery. Polyurethane is traditionally formed by the reaction of diisocyanate with polyol. Most of the new polyurethanes are produced by the reaction of aromatic diisocyanate with DLs. DLs include ethylene or propylene glycol, polyether DL, aliphatic polyester DL, and silicone DLs.

Polyurethane foam structure

The structure of foam is classified into two categories: open cell and closed cell.

The open cell foam structure is soft and flexible. In this structure, cell walls are split with surface bubbles. Then they fill all the spaces in the material with air. This causes the formation of soft foam. The difference between polyurethane and polyurea

The similarities and differences between these two types of foam are:

Polyurethane: refers to a polymer material that is synthesized from the reaction of isocyanate with polyol.

This reaction requires a catalyst and a certain temperature.

Polyamide: refers to a polymer material that is combined with uranium urea. which is synthesized from the reaction of isocyanate with polyamine.

This reaction does not require a catalyst and a special temperature.

Urea bonds are more stable than urethane bonds.

Because urea bonds are stronger than urethane bonds. properties and characteristics

Polyurethane foams are important because of their special characteristics. The properties and characteristics of polyurethane foam include the following:

*Hardness (shows the amount of sinking of an object against pressure)

* Increasing load and pressure bearing capacity

* High flexibility

* High resistance to pressure and impact

*Resistant to water, mold and fungus, environmental and atmospheric corrosive factors

* Electrical insulation

* The reaction is done in a short time.

*low price

* High adhesion with different surfaces

*Non-toxic and approved for use near drinking water

*In sausage packaging

The method of making polyurethane foam

Polyurethane is a thermoset polymer, which is produced by combining isocyanate with polyol (polyol) in the presence of some other chemical additives.

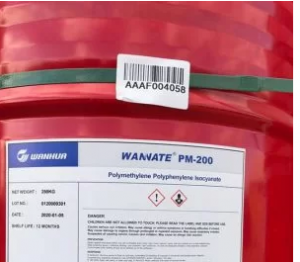

Polyurethane foam raw materials (pu raw materials) As mentioned earlier, polyurethane refers to polymers that have a urethane bond. The urethane bond is formed by the reaction between two isocyanate and hydroxyl groups. The most important and main isocyanate constituents of polyurethane materials are listed below:

* 2 and 4 or 2 and 6 toluene diisocyanate, which is also seen with the abbreviation TDA.

TDI is one of the members of the isocyanate family. which is widely used in the production of polyurethane. * 4 and 4 or 2 and 4 diphenylmethane diisocyanate * 1 and 6 hexamethylene diisocyanate

Methyl diphenyl diisocyanate, also known as MDA. (MDI)

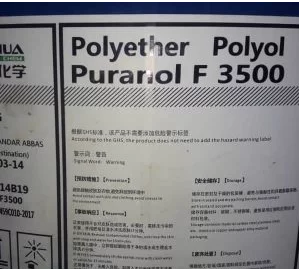

Polyol refers to compounds consisting of two or more hydroxyl groups. The most important and main polyol forming polyurethane raw materials is given below.

*Polyether polyol

*Polyester polyester

*Polycarbonate Polyol

*Polycaprolactone Polyl

*Acrylic polyol

However, we need additional materials to form polyurethanes. These additives are described below.

*Silicone surfactant * Catalyst (tin catalyst (Tin or Cosmos) and amine catalyst (33lv, Dabco)) Catalyst has an effect on the polyurethane process and the improvement of transverse connections.

Dabco Catalyst (Amen, 2LV) in Polyurethane Foam Production

The Dabco Catalyst is one of the raw materials needed to make polyurethane foam. DABCO (Amen LV 33) is used as an open catalyst for the following:

*Polyurethane formation of alcohol and isocyanate monomers and pre -polymers.

*The reactions of Biiless – Hillman and Maurita – Billis – Hillman from unsaturated aldehydes and ketones and aldehydes.

The amines are primarily catalyzing the reaction between water and isocyanate. However, they are often referred to as the “blower” catalyst. They have various activities in promoting the reaction between polyol and isocyanate (gel reaction). A combination of different amines is used to balance the gel and breathe reactions to control the foam process sufficiently. Amen catalysts affect the physical properties and quality of the end product. Conventional polyurethane amine catalysts include tricethylelediamine pentamethydiethyletenetriariamine and Dimethylcyclohexylamine.

Conventional amine catalysts can be used in a variety of polyurethane foam applications, including car seats, furniture and uphols, refrigerators, ceilings and wall coverings. Every day these durable products make our lives easier and safer. So we are seeing the growing growth of these products every day. Tin Tin or Casmus Catalyst in the production of polyurethane foam Generally, tin compounds (II) are used as catalyst for sponge production. The tin catalyst storms the gel reaction. If the polymer fails to perform the polymerization reaction properly, the tin catalyst causes the foam gap or possibly collapse. Casmus is a basic catalyst for the production of polyurethane foam, catalysts for silicon tires, polyurethane tires and polyurethane coatings. Polyurethane application Recently, we are witnessing the growing growth of polyurethane. Yurthanes are used in the world in a variety of ways such as soft foam, hard foam, elastomers, thermoplastic, resin, paint, coating, adhesive and a variety of puppets. And it has a lot of use in sofa sponge, hard resins, flooring, cars, glue, building insulation, home appliance insulation, panel sandwich walls and soil buried pipes. Other applications of polyurethane include the following.

*In the construction of the heart, the kidneys are used.

*Are used as bone alternatives in the body.

*In cover foams (used as building insulation)

*The wood industry, known as the Polyurethane wood foam.

This foam is a good replacement in the wood industry.

Polyurethane insulation

Polyurethane, known as thermal insulation. Their applications change with the change of density and the structure of its cells. These materials can be used as sound insulation or heat.

The impact of polyurethane on health

Polyurethane polymer is a reaction that is chemically ineffective. According to the US Department of Safety and Health, no prohibition on polyurethane has been reported. This is due to the lack of carcinogenicity. This commercial material is a solid and combustible combination. As is said, one of the main disadvantages of polyurethane foam is their flames. Polyurethane forms toxic substances such as carbon monoxide and hydrogen cyanide by decomposition or heat. To this end, these products must be free of flame inhibitors. Isocyanate is one of the main raw materials of polyurethane foam. As can be seen repeatedly in all articles. It is known as skin sensitive and breathing. Therefore, exposure to these substances may be harmful to human health. For this reason, caution is necessary when using this substance.